MusicallyInept

Newbie

Hello,

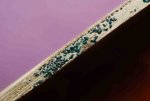

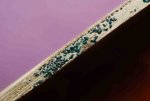

A few weeks ago, I bought an accordion (1960 - I'm told - Settimio Soprani Dick Contino Model), and I've been learning to play it while lurking to glean information about how to maintain and care for it. It seems that the first thing to do in order to rectify a leak in the bellows is to replace the black chamois gasket with a modern foam type. I pulled the bellows pins without any incident and everything separated fine. When I looked closer, the chamois seems to be in good shape, but the hard glue that holds it to the bellows is brittle and easily separating - no big deal. However, the sealing surface on both the treble and bass sides felt like course sandpaper in places. Looking closer, I was confused to see brass flecks with verdigris from reacting with the chamois gasket

Looking closer, I think I figured out why they are there. It looks like the cases were painted white and then brass chips were applied before the fine tiger-stripe celluloid was applied. Whatever brass chips weren't covered by celluloid (or that accidentally got embedded on the outside of the celluloid) were free to react with the chamois. Here are a few more pictures of the accordion and the finish to better illustrate:

When I put on the new-style foam gasket, I want to smooth out the gasket surface to make the best seal I can without damaging the instrument in the process. I mess around with woodworking, and have done some repair to other instruments before, so I have pretty much all the supplies I should need, but I want to run my plan of attack by you guys to make sure I'm not messing up (I've never worked with celluloid).

Thanks!

Ron

A few weeks ago, I bought an accordion (1960 - I'm told - Settimio Soprani Dick Contino Model), and I've been learning to play it while lurking to glean information about how to maintain and care for it. It seems that the first thing to do in order to rectify a leak in the bellows is to replace the black chamois gasket with a modern foam type. I pulled the bellows pins without any incident and everything separated fine. When I looked closer, the chamois seems to be in good shape, but the hard glue that holds it to the bellows is brittle and easily separating - no big deal. However, the sealing surface on both the treble and bass sides felt like course sandpaper in places. Looking closer, I was confused to see brass flecks with verdigris from reacting with the chamois gasket

Looking closer, I think I figured out why they are there. It looks like the cases were painted white and then brass chips were applied before the fine tiger-stripe celluloid was applied. Whatever brass chips weren't covered by celluloid (or that accidentally got embedded on the outside of the celluloid) were free to react with the chamois. Here are a few more pictures of the accordion and the finish to better illustrate:

When I put on the new-style foam gasket, I want to smooth out the gasket surface to make the best seal I can without damaging the instrument in the process. I mess around with woodworking, and have done some repair to other instruments before, so I have pretty much all the supplies I should need, but I want to run my plan of attack by you guys to make sure I'm not messing up (I've never worked with celluloid).

- This part is done -> Used the non-sharp edge of a razor blade (the part perpendicular to the sharp part) held at a low angle to knock off the loose brass and burnish the bits that are very well embedded

- Use a fine brass brush and some alcohol to clear out as much embedded verdigris as possible before encapsulating what's left in shellac

- Seal the gasket surface with shellac and prevent possible affects from later coats of vinyl sealer and/or lacquer

- Fill small gap in the celluloid seam with a smear of epoxy

- 1-2 more coats of shellac

- lightly sand, then apply Behlen's vinyl sealer, Behlens instrument lacquer, or both

- put back together and continue learning accordion

Thanks!

Ron