First, it really is capable of a very nice full tone. The bassoon and middle cassotto reeds along with the other two middle reeds and a piccolo come together nicely, the musette is very ou la la ( triple, or triple with bassoon) and the middle alone and bassoon and middle are both very usable. The bass reeds are apparently machine as opposed to hand but have excellent response none the less.

The thing is large- but (for me) quite manageable. The weight (33 pounds/ 15 kilos with straps) is at the upper limit of my tolerance when standing for more than thirty minutes or so, but is (as you'd expect) no issue when seated.

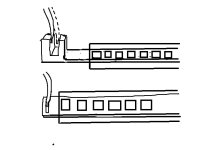

The "curtain rod" shoulder strap brackets - to my surprise- are quite comfortable.

The keyboard feel is excellent- good response and relatively short travel on the keys. The 45 keys are easy to reach (45, but slightly narrower without the cramped feel (to me) of the really compact keyboards (a piano player for decades). The array of thumb slides for register changes ( two on the front keyboard edge, two on the back for the bass) are not really useful to me, and a bit difficult to get used to as they constantly hit my thumbs. I suppose time will let me get used to them both in terms of the annoyance in feel and in making use of the quick switch they offer. (basoon middle, bassoon middle piccolo- should be bassoon piccolo... see below)

The three row c griff chromatic option for the bass works well but I really have to push my wrist well up under the bass strap to get at it with any facility.

My particular Morino had the plastic linkage at the end of the bassoon slide in the foundation plate for the shift arm broken off through plastic fatigue- probably aggravated by the hammering effect of the operation of the front edge thumb slides linkage over 60 years. Originally the bassoon slide was permanently on as a result of the broken slide, but after a lot of tinkering and a great deal of very bad language I successfully switched the cassotto middle reed slides with the bassoon slides. This means the middle reeds in the cassotto are always on, but the bassoon is switchable. All well but for low/high and the bassoon alone now comes out as low/middle- quite livable for me.

The thing is large- but (for me) quite manageable. The weight (33 pounds/ 15 kilos with straps) is at the upper limit of my tolerance when standing for more than thirty minutes or so, but is (as you'd expect) no issue when seated.

The "curtain rod" shoulder strap brackets - to my surprise- are quite comfortable.

The keyboard feel is excellent- good response and relatively short travel on the keys. The 45 keys are easy to reach (45, but slightly narrower without the cramped feel (to me) of the really compact keyboards (a piano player for decades). The array of thumb slides for register changes ( two on the front keyboard edge, two on the back for the bass) are not really useful to me, and a bit difficult to get used to as they constantly hit my thumbs. I suppose time will let me get used to them both in terms of the annoyance in feel and in making use of the quick switch they offer. (basoon middle, bassoon middle piccolo- should be bassoon piccolo... see below)

The three row c griff chromatic option for the bass works well but I really have to push my wrist well up under the bass strap to get at it with any facility.

My particular Morino had the plastic linkage at the end of the bassoon slide in the foundation plate for the shift arm broken off through plastic fatigue- probably aggravated by the hammering effect of the operation of the front edge thumb slides linkage over 60 years. Originally the bassoon slide was permanently on as a result of the broken slide, but after a lot of tinkering and a great deal of very bad language I successfully switched the cassotto middle reed slides with the bassoon slides. This means the middle reeds in the cassotto are always on, but the bassoon is switchable. All well but for low/high and the bassoon alone now comes out as low/middle- quite livable for me.

Last edited: