FlickFlackAccordions

Member

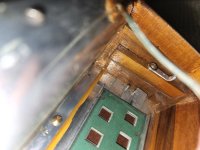

On my previous post I mentioned the register switches not all working. I found the offender (I believe) (Maybe) (I sure hope)

In the attached pictures, I believe the rightmost switchplate has been somehow bent over that screw, and is causing several levers to not function correctly.

How should I go about bending it back into place?

Alternatively, possibly more dangerously, what is I cut out the bit of the switch plate that is stuck on the screw? Would that have any problems? That length of plate isn't connected to anything, so my thinking is that It would be fine.

In the attached pictures, I believe the rightmost switchplate has been somehow bent over that screw, and is causing several levers to not function correctly.

How should I go about bending it back into place?

Alternatively, possibly more dangerously, what is I cut out the bit of the switch plate that is stuck on the screw? Would that have any problems? That length of plate isn't connected to anything, so my thinking is that It would be fine.